- SYSTEM 16 METRIC SERIES

THE WALTER

SYSTEM 16

METRIC(MM)WELDING

TABLES

.jpg)

D16 STEEL TABLE

D16 CAST IRON TABLE

D16 STEEL NITRIDED TABLE

D16 CAST IRON NITRIDED TABLE

SYSTEM 16 METRIC ACCESSORY SETS

VIEW ALL ACCESSORY SET

D16 SET1(28 Piece kit)

D16 SET2(40 Piece kit)

D16 SET3(68 Piece kit)

D16 SET4(96 Piece kit)

D16 SET5(116 Piece kit)

- SYSTEM 28 METRIC SERIES

THE WALTER SYSTEM 28 METRIC(MM)WELDING TABLES

D28 STEEL TABLE.jpg)

D28 CAST IRON TABLE

D28 STEEL NITRIDED TABLE

D28 CAST IRON NITRIDED TABLE

SYSTEM 28 METRIC ACCESSORY SETS

VIEW ALL ACCESSORY SET

D28 SET1(28 Piece kit)

D28 SET2(40 Piece kit)

D28 SET3(68 Piece kit)

D28 SET4(96 Piece kit)

D28 SET5(116 Piece kit)

Plasma nitriding is an advanced thermochemical surface treatment that utilizes ionized gas (e.g., nitrogen and hydrogen) to diffuse nitrogen ions into metal surfaces. Key advantages include low-temperature processing (typically 400–600°C)...

Key Process Steps:

1.Vacuum Chamber Pretreatment: Evacuate to 10⁻³–10⁻⁴ mbar to remove contaminants.

2.Plasma Generation: Introduce N₂/H₂ gas mixture (3:1 ratio) and apply 400–1000V pulsed DC voltage to generate glow discharge.

3.Nitrogen Ion Bombardment: High-energy nitrogen ions bombard the surface, forming a diffusion layer and compound layer.

4.Cooling & Post-Treatment: Slow cooling to room temperature, followed by optional polishing/coating.

2. Plasma Nitriding of Q355 Steel

Material Properties:

Q355 is a low-alloy high-strength structural steel containing C (≤0.20%), Mn (≤1.60%), and Si (≤0.55%).

Typical applications: Construction machinery, bridge components, pressure vessels.

Process Parameters:

Temperature: 480–520°C

Duration: 8–20 hours

Gas Ratio: N₂:H₂ = 3:1

Pressure: 2–5 mbar

Performance Enhancements:

Surface Hardness: 700–900 HV (3–4x improvement over untreated steel)

Nitrided Layer Thickness: 0.1–0.3 mm (compound layer: 5–15 μm)

Wear Resistance: >60% reduction in wear rate (ASTM G99)

Corrosion Resistance: 500-hour neutral salt spray resistance (ASTM B117)

Advantages:

✅ Minimal distortion (<0.05 mm/m, ideal for precision components)

✅ No hydrogen embrittlement risk (vs. gas nitriding)

3. Plasma Nitriding of HT300 Cast Iron

Material Properties:

HT300 is gray cast iron with C (3.0–3.3%), Si (1.8–2.2%), and flake graphite microstructure.

Typical applications: Machine tool beds, engine blocks, heavy equipment bases.

Process Challenges:

Graphite Interference: Flake graphite reduces nitrogen diffusion efficiency.

Temperature Limitation: Exceeding 550°C risks matrix softening.

Optimized Parameters:

Temperature: 450–500°C (lower than steel processing)

Duration: 12–30 hours (extended to compensate for graphite)

Gas Ratio: N₂:H₂ = 4:1 (higher nitrogen potential)

Pulse Frequency: High-frequency pulses (>1 kHz) enhance plasma penetration

Performance Enhancements:

Surface Hardness: 500–750 HV (2–3x improvement)

Nitrided Layer Thickness: 0.08–0.2 mm (compound layer: 3–10 μm)

Anti-Galling Properties: 40% reduction in sliding friction coefficient (SAE 214201)

Fatigue Resistance: 50% increase in cyclic load lifespan

Advantages:

✅ Retains vibration-damping properties of cast iron

✅ Avoids surface roughness issues seen in liquid nitriding

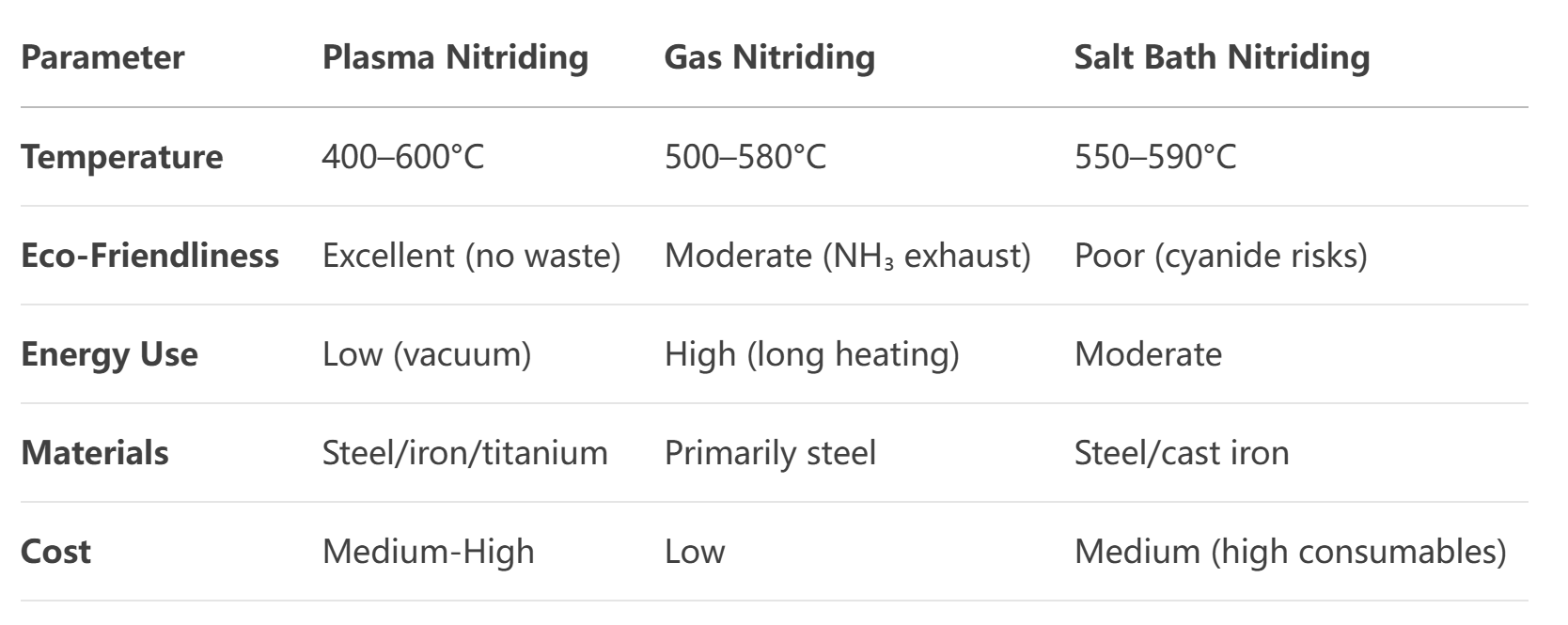

4. Comparison with Other Nitriding Methods

5. Application Cases

Q355 Steel: Hinge components for port cranes achieved 8-year service life (vs. 2 years untreated).

HT300 Cast Iron: CNC machine tool guides showed 650 HV surface hardness, tripling maintenance intervals.

Conclusion:

Plasma nitriding offers high-efficiency, eco-friendly surface hardening for Q355 steel and HT300 cast iron, particularly suited for precision components requiring dimensional stability. Optimized parameters significantly enhance wear resistance, fatigue strength, and corrosion resistance, meeting demands for high-end industrial equipment.

Need process validation? Contact our lab for a free sample treatment report!

WALTER CHINA Group:

WALTER Series

Information

Customer Reviews

Customer Gallery

Terms & Conditions

Privacy Policy

Return Policy

About Us

.jpg)

(1).jpg)

.jpg)